Note added at end of 2017:

For some reason this page is the most popular page on my blog, and there has been a stream of comments and discussion. I am glad if it is useful but I feel the need to point out that all of the alternators I build now have 3 coils for every 4 poles.

For example 12 magnets and 9 coils as in the 2F design.

I have used several other arrangements but this 10 pole 12 coil one below is the whackiest ever, and although it does work (very well) I am not suggesting it’s the best solution.

– Hugh 2017-

Coils wound in pairs using 2-in-hand 1.6mm diameter wire. Each coil has 37 turns in the one we did for the workshop.

Coils wound in pairs using 2-in-hand 1.6mm diameter wire. Each coil has 37 turns in the one we did for the workshop.

Coils in each pair are roughly ‘in phase’ if one is flipped over as shown. (Actually there is still 30 degrees of electrical phase difference between them, so they are each 15 degrees off the total combined phase angle, which means about 3.5% loss of voltage.)

Pairs that are opposite to each other are ‘in phase’ if connected backwards as shown above. Then the phases are connected in star by linking all of the starts to a neutral (black wires).

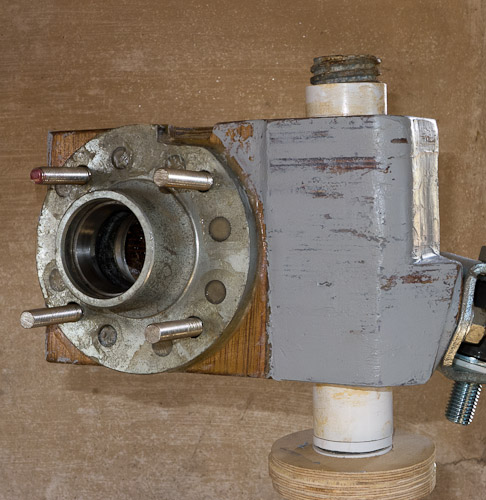

This alternator uses 10 poles made from ferrite magnets. When magnets are fitted tightly together like this it makes sense to me to use smaller coils with smaller holes and benefit from the shorter turns in each coil. It’s fun to try something different anyway.

The same winding could work with 14 magnets. But I see no merit in doing this. Maybe somebody can? The inner turns would get more induction from smaller poles, but there would be more leakage flux.

“The City paid more than $20,000 for a Helix turbine, famous for other “worst turbine install in history” accomplishments, that generated an incredible 34 kWh in the two years since it was installed on a parking garage.

“The City paid more than $20,000 for a Helix turbine, famous for other “worst turbine install in history” accomplishments, that generated an incredible 34 kWh in the two years since it was installed on a parking garage. (This photo shows a Gaia wind turbine for contrast. It’s just an example of a well designed and properly sited small wind turbine that can make economic sense, unlike the rooftop blunders that give wind energy a bad name.)

(This photo shows a Gaia wind turbine for contrast. It’s just an example of a well designed and properly sited small wind turbine that can make economic sense, unlike the rooftop blunders that give wind energy a bad name.)

is requiring that the assets of Helix Wind Corp and Helix Wind Inc, both Nevada Corporations, be sold

is requiring that the assets of Helix Wind Corp and Helix Wind Inc, both Nevada Corporations, be sold