Chris Olsen has taken a new turn in his wind turbine experiments and built a direct drive neo magnet machine for use with the Midnite Classic controller.

Older stuff by Chris includes a gallery showing how to cut out a magnet disk with a cutting torch. Also his work with chain driven ferrite magnet machines on this blog here. And here

It is quite small for a 20 pole generator – only 330 mm rotors. The whole thing is covered to protect against snow and ice build up which has been a big problem in Chris’s Wisconsin environment.

2 x 1 x .5″ N42 bars with countersunk holes on both sides so they can be bolted to the rotors with small taper head stainless steel bolts. Air gap is 17 mm between magnet faces.

15 coils of AWG 14 wire for this stator and there is 70 turns in each coil.

Star/wye connected: 53 volts at 100 rpm and 205 at 380 rpm.

In delta: 120 volts from it @ 380 rpm.

The resistance: 1.13 ohm in wye and .35 in delta.

“I wanted to do a direct drive because I believe I will get better rotor acceleration with a direct drive to take advantage of variable winds. The geared machines “lag” a tiny bit when wind speed increases because the rotating mass must be accelerated much more than direct drive mass. I believe that will help me keep the rotor in a more ideal TSR range at all times, and harvest more energy from the wind. It might be very, very small amount. But over time it adds up. And when you have a wind turbine that already operates over 32% overall efficiency thruout the entire wind speed range, it gets harder and harder to “tweak” it to get more. So you have to pay attention to every last detail, including accelerating rotating mass!”

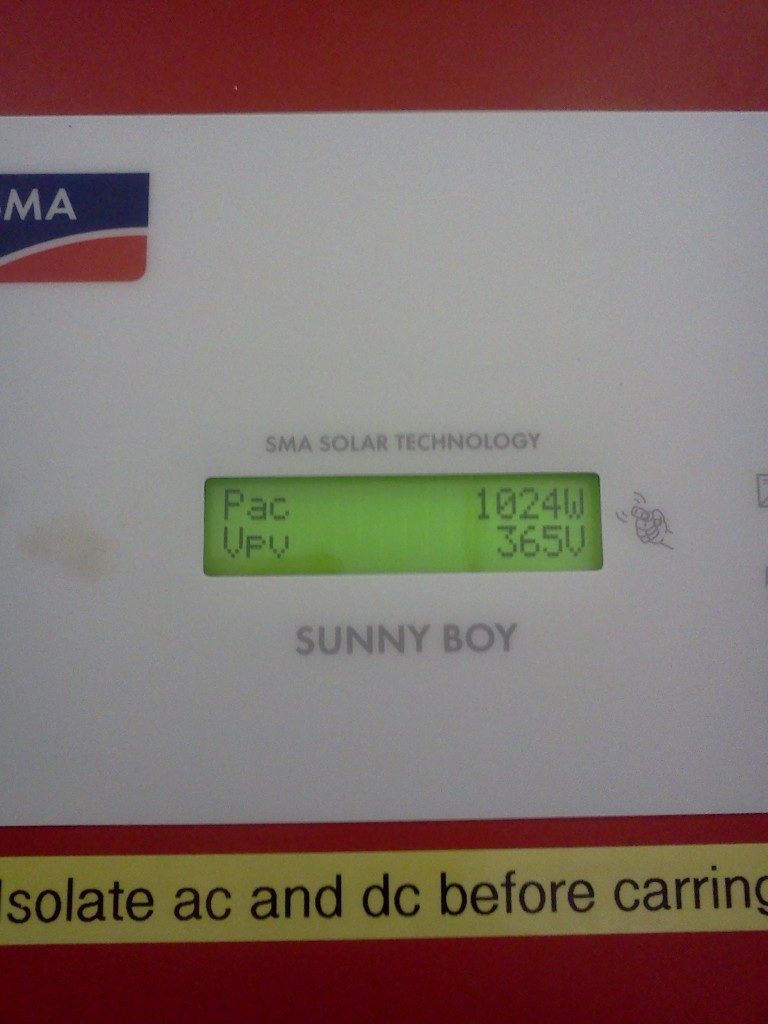

In these photos the generator has been modified to work well in star/wye with a 3.2 metre diameter rotor. “I pulled the rear generator rotor and added some shims to it to increase the air gap and lower the voltage some. Then programmed the controller to “flatten” the power curve and don’t let it go over 148 volts.”

-

-

“I use these shims between the rotors to set the air gap”

-

-

“This a shot for Hugh to show how close those mags run to the stator”

-

-

-

-

“The stator will be 12mm thick after I get it out of the press, and I figured for a 17mm air gap”

-

-

“the screens will fix the problem with the snow by just plugging up, and yet still allow air to flow thru for summer”

-

-

“I put stainless steel bushings in the stator so the casting can’t be crushed, and use spacers and shims to set the stator to front gen rotor clearance. “

-

Chris has started a new web site with details of how to build this project here (but only the first pages are available)

Watch this space.

“The Classic controller that boB and Robin Gudgel invented opened up a whole new world in what I can do in wind turbine design. I can “tweak” a power curve on my laptop and load it to the controller over wireless. Then sit there in the comfort of my office and watch it perform, and log the output data from it and analyze what the change did. It is very cool. And fun too! 🙂 “

ask information about water pumping, I advise them to start with report KD 490 as this gives an overview of four different ways how to pump water with a windmill and it gives references to all my relevant reports for detailed information about a certain choice.”

ask information about water pumping, I advise them to start with report KD 490 as this gives an overview of four different ways how to pump water with a windmill and it gives references to all my relevant reports for detailed information about a certain choice.”