- The start wires go through a hole.

- The coil is finished and taped

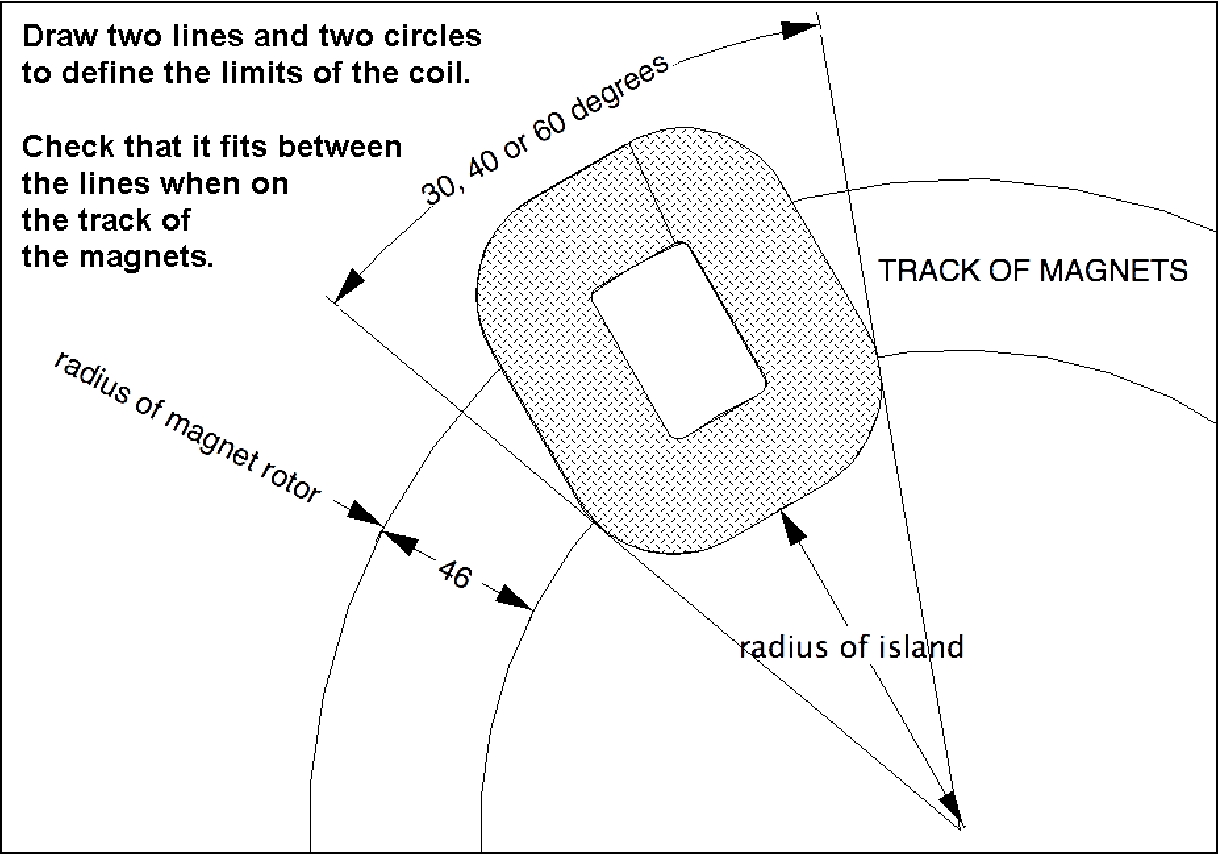

- The coil fits between the two lines.

- wire tensioning device

- Stator coils fit perfectly.

- Wires through middle of coil end

During this workshop we made a stator for a 24 volt machine with 3 metre diameter blades, using the standard recipe of 55 turns of 1.6 mm diameter wire (2 in hand).

Here are some photos of the details. Click on a photo to see it full size, and in some cases view more notes.

We used a simple device to make sure the tension was the same in each coil (thanks to Eddy at Tripalium)

We pushed the wires through a small hole in the winder at the start to anchor them rather than wrapping them around the shaft of the winder (after which they are hard to straighten out).

We placed the first coil in the space drawn out for it on paper 40 degrees in this case, to check the size was right (and it was, within one mm yes).

The result was a set of coils that were the same weight within 1% and that fitted perfectly in the stator.

The ‘finishes’ are a bit stiff and they tend to lift the fibreglass cloth and introduce air into the casting (no big deal) so Audun suggested threading the finishes through the end of the coil as in one of the above photos. We were too late to try this but I can see it making some neat stators too.

Hello Hugh,

I have 24 magnet blocks of grade N52 and size 2 x 1 x 1/2 Inches (50.8 x 25.4 x 12.7 mm) in my hand which are imported, as I couldn’t find any local supplier sells Neo magnets. I also have 1.4mm magnet wire spool.

All supplies and common measurement system are in metric in my country. Hence, I’ve bought metric edition of your Wind turbine recipe book.

I’m aiming for 3000mm turbine recipe to charge my 24v battery system. I’m aware of refining the coil winder spacer’s dimensions and nail positions, so that the resulting coil inner dimensions equals the used magnet block, along with island diameter for stator mold.

I’ll be using 350mm diameter steel disk for magnets as per recipe.

For coil winding the recipe says, 55 turns of [email protected] mm enamelled copper wire for 24v system.

My question is , would you suggest refining number of turns per coil for what currently in hand ( Grade N52 2 x 1 x 1/2 inches magnets and 1.4 mm enamelled copper wire) ?

Thank you,

Assem

hi Assem,

My feeling is that you ought to try to wind the coils with 3 in hand 1.4 mm dia wire. Maybe try using a bit fewer turns but at least 50 turns. I’d check the coil fits and maximise the turns. You can either use 55 turns and a thicker stator or use fewer turns and a thin stator. Either way should work with your stronger magnets. Maybe a bit of each using 50 turns and seeing how much thicker it needs to be to fit the space if any.

It’s not life and death to get the right number of turns etc. If you do not get a high enough voltage output then the turbine will simply run a bit faster and this will make very little difference except in very low winds. But if you want to get good output then I do recommend using 3 wires rather than 2 as you will risk overheating with only 2 wires at 1.4 diameter.

have fun

Hugh

Hi Hugh,

Thank you very much for this valuable input!

So, I’ll try 3 in hand with over 50 turns and compromise in a bit thicker stator as the magnets are stronger.

Your extraordinary effort to spread knowlage of this field is much appreciated.

Regards,

Assem

Thank you very much for your valuable input!

So, I’ll try 3 in hand and compromise in a bit thicker stator as the magnets used are stronger.

your extraordinary effort to spread knowledge of this field is much appreciated.

Regads,

Assem